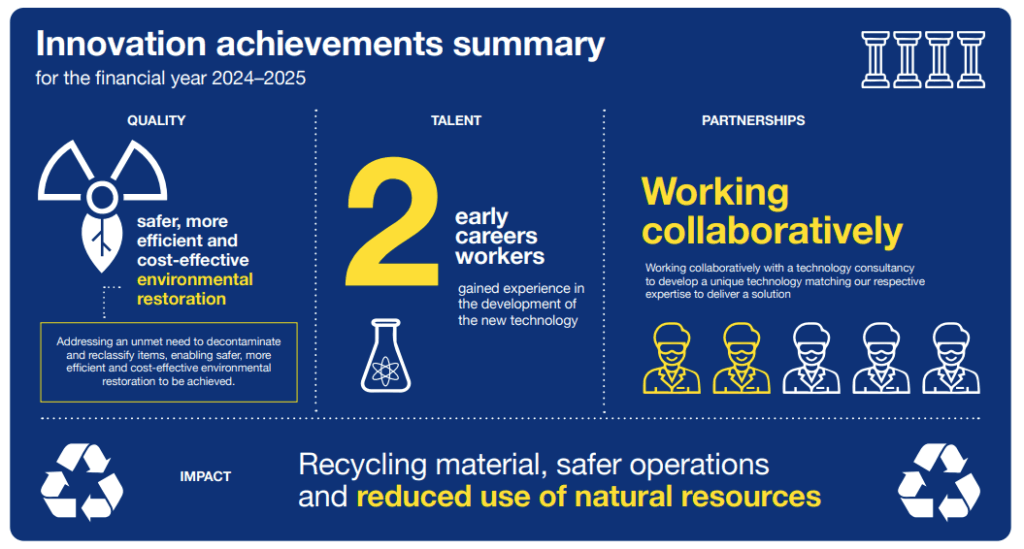

A significant breakthrough by the team at UKNNL means that materials previously classified as radioactive waste can now be decontaminated in minutes, not days, using existing standard equipment – the first time this process has been applied in a nuclear context.

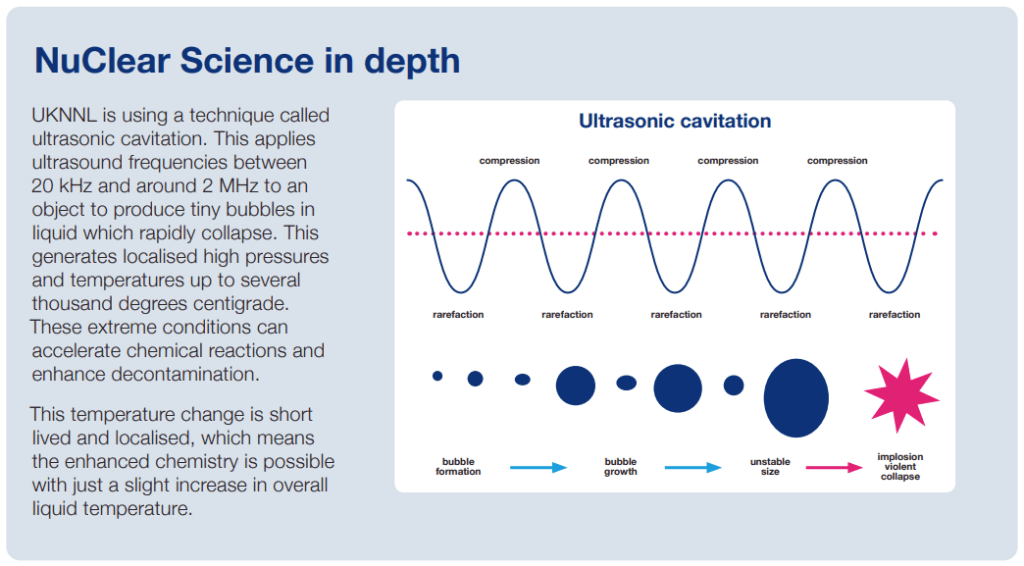

Researchers at UKNNL are working on plant decommissioning challenges in nuclear waste where deposits may arise from several scenarios, such as grease, solvent or paint, or where solids need to be broken up to enable them to be moved, for example from the bottom of a tank. Using existing low-frequency ultrasound technology can decontaminate waste materials in minutes. The process creates hot energy spots which effectively decontaminate the material’s surface.

Significant efficiencies in waste management – including cost savings – will become possible once this technology is fully developed. Cost savings would be realised through more efficient processing of wastes, faster decontamination times and reduced use of reagents compared with current methods.

This breakthrough was made by researchers working to adapt existing standard industrial equipment to withstand the challenging conditions inherent in nuclear environments, including exposure to strong acids, alkalis and radiation. Adapting existing technology and equipment is a strong innovation approach, saving time and money versus developing completely novel solutions.

UKNNL is now partnering with experts who manufacture industrial ultrasonic devices to deploy this technique in a nuclear setting.

Read on to find out about how ultrasound can facilitate decontamination, how UKNNL is developing technology and skills, and how it’s collaborating with others to develop sustainable solutions.

What led us to ultrasound

Applying intense bursts of energy on a small scale, including microwaves, electricity and ultrasound, can speed up a chemical process and separate contaminants from materials. Initial testing of ultrasound in the laboratory showed promising results in removing surface deposits that cannot be removed by other methods.

The initial focus on deploying this technology is to support waste management and decommissioning, but this is a versatile technology with potential applications in multiple settings.

“ Ultrasonic treatment is a promising technology for decontaminating of items and vessels. It has the potential to mobilise contamination which has become adhered to surfaces, it can remove blockages in pipework and it has the potential to improve the effectiveness of decontamination reagents. ”

Sarah Bibby

Technical Manager, Sellafield Ltd

Developing alternative uses of ultrasound

Industrial and medical applications of ultrasound are widespread, such as in food and drink manufacturing, defect detection, and welding. Some, such as pregnancy scans and plastic welding, use very-high-frequency soundwaves. Heavy industrial cleaning ultrasound processes generally use lower frequencies.

Alongside partners, UKNNL carried out research to understand if it was possible to create a low-frequency ultrasound device suitable to be used in the specific environments found on nuclear sites. The chemical environment found in the nuclear sector can be harsh. Equipment can be exposed to concentrated acid or alkali and may involve full immersion in liquids. Standard low-frequency industrial ultrasound equipment is not resistant to these conditions.

Developing this technology has provided unique opportunities to foster advanced nuclear skills. UKNNL scientists have now applied it to decontaminate pipework from a nuclear facility currently undergoing decommissioning. Decontaminating pipework can be particularly challenging as it is difficult to access, expansive, irregular in shape, sometimes containing bends, and can have build-ups of deposits.

Project impacts

As the UK continues to harness the potential of clean energy from nuclear power, there will be a continued need to decontaminate the waste generated. This project creates a process that not only enables previously contaminated waste to be recycled through standard channels, but also reduces the time taken to decontaminate waste, achieving it in just minutes compared to the previous standard of one week.

As part of the project, two early career scientists have developed critical skills and gained practical experience in developing a new technology. This kind of experience is necessary to support the development of a skilled nuclear workforce, an imperative for the UK’s sustainable future.

What’s next?

Work to develop the technology so it can be used in operational nuclear settings is currently underway in our Preston Laboratory. UKNNL is building a partnership with an organisation with expertise in manufacturing ultrasonic devices to develop a version of our laboratory scale equipment suitable to be used on a nuclear site.

“ I’m excited that we are working to develop this promising technology, it has a lot of potential to enhance the sustainability of a range of nuclear operations. ”

Luke O’Brien

Fellow, UKNNL

Development of this ultrasonic device will also benefit from collaboration across teams within UKNNL. The decontamination team, who had the initial idea, will soon start work to further develop and prove the efficiency of this technology in a real industrial setting. They will work with operators in the active handling facility at our Windscale laboratory and at our residue processing and decontamination facilities at the Preston laboratory.

This novel decontamination method could become part of a wider decommissioning toolkit with the potential to reduce both costs and hazard. Critically, the breakthrough has shown waste can be reclassified and recycled through standard channels by removing deposits from surfaces.

“ I’m pleased work with ultrasonics is continuing to be developed. Having had the opportunity to work on early iterations of the technology and observing the ease with which heavy contamination could be removed from piping which had been recovered from an active facility, it was clear this is a great tool for decontamination, one that can easily be used in conjunction with other techniques such as Electrochemically Assisted Surface Decontamination (EASD), removing contamination and producing a waste product that can be classified as very low level waste. ”

Peter Durham

Senior Research Technologist Waste & Residues Processing UKNNL

Nurturing Innovation

It’s imperative to be agile to solve some of the critical challenges of our generation. UKNNL’s approach to innovation harnesses the best ideas from both inside the organisation and across the world.

A structured approach enables swift identification of projects worthy of further investment or with potential to fail fast. Funding is available for colleagues with ideas which need pursuing. Teams work on a variety of projects with varying levels of resource allocated, depending on how well-defined the scope is. Timelines can vary from five day innovation sprints to six-week periods of focused work.

The process also identifies when UKNNL can’t develop a solution alone, partnering with external organisations where needed to make the best progress, rapidly.

Open Nuclear is UKNNL’s innovation platform, which invites innovative thinkers globally to contribute to solving defined challenges and developing innovative technology. Open Nuclear is keen to work within a partnership model which brings in divergent thinking, shares expertise, and co-develops technologies for shared rewards.

Contact engagement@uknnl.com for more information.