Plutonium (Pu) is one of the most scientifically interesting and amazing elements in the periodic table. It has properties like no other element and there is still much to understand after many years of research into this member of the actinides. With the UK having the world’s largest inventory of separated civil plutonium – a result of civil reprocessing of nuclear fuels – understanding the science and its behaviour is important.

UKNNL is collaborating to understand more about what happens to the properties of plutonium materials during extended storage, but also to spot opportunities to harness its unique capabilities, including a breakthrough leading to new capabilities to fuel spacecraft power and heating units.

UKNNL’s expertise and world-leading facilities play a vital role in supporting national policy development and maintaining critical nuclear expertise in plutonium management. It is a UK government priority to ensure the safe and secure management of these plutonium materials while working towards immobilisation and disposal of the inventory to put this material beyond reach.

Collaborative research and long-running partnerships with Sellafield Ltd and the Nuclear Decommissioning Authority (NDA) support nationally important missions across plutonium science. This facilitates access to the UK’s civil plutonium inventory and provides UKNNL with both funding and technical co-operation, enabling research impossible elsewhere in the UK.

Read on for more insight into the challenge of storing and managing the UK’s plutonium inventory and a breakthrough which means this nuclear waste legacy has the potential to be a fuel of the future.

The plutonium challenge

Plutonium is an artificial element produced in nuclear reactors when uranium fuels are irradiated. It exists in a variety of different isotopes and attracts attention due to its high radiotoxicity and applications in nuclear weapons.

From the 1950s until 2022, the UK reprocessed used nuclear fuel for waste management, commercial and strategic reasons for organisations in the UK and overseas. During this reprocessing, plutonium was separated from uranium and other fission products.

The UK’s civil plutonium inventory – the largest in the world – is stored at custom-built facilities that ensure its safety and security at Sellafield in Cumbria. These stores require careful stewardship before long-term government policy solutions for plutonium disposal are implemented.

Plutonium is stored in packages – specially designed containers which isolate the highly radioactive element to keep it safe. UKNNL’s research to support Sellafield Ltd’s stewardship of plutonium stores includes carrying out research to understand how the condition of the storage packages, the gas composition within, and the plutonium itself changes over time, alongside a programme of surveillance to verify the condition of packages.

Specialised research and characterisation of plutonium materials can only be carried out in secure facilities such as UKNNL’s Central Laboratory. This work is vital to understanding how stored plutonium changes over time.

“Future progress in Pu Sciences at UKNNL is dependent on new analytical and experimental techniques integrated with alpha gloveboxes. This is highlighted by the installation of a Thermogravimetric Analysis-Mass Spectrometer (TGA-MS) that will enable UKNNL to develop a better understanding of plutonium oxide (PuO2) surface chemistry. ”

Chris Gregson

Postdoctoral research scientist in plutonium, UKNNL

Progress on plutonium

Since 2010, in collaboration with Sellafield Ltd, UKNNL has made significant progress with research into the unique challenges presented by plutonium. Research has improved understanding, contributing to world-leading science, which helps safeguard vital skills for the nuclear industry, particularly related to handling and storing of radioactive materials. This new understanding underpins the UK’s plutonium management strategy, demonstrating it is robust, safe and scientifically sound.

UKNNL uses experimental studies of plutonium packages and powders together with computational modelling to build a picture of what’s happening inside those in the inventory. Modelling and simulation help to understand the temperature changes, water vapour diffusion and the effects of radiation in different package types.

This modelling has been benchmarked against data from plutonium storage packages from the two plutonium reprocessing plants at the Sellafield site. This work is complemented by extensive UKNNL laboratory studies on plutonium and similar materials, alongside basic science studies at universities, to understand the interplay between radiation, porosity and the atmosphere inside the canisters.

The heritage of plutonium science research within UKNNL is the bedrock of the skills and capabilities required for the future mission of the NDA and Sellafield Ltd plutonium disposition programme. This programme is the cornerstone of UKNNL’s plutonium research agenda, skills development and experimental base, but UKNNL’s role as a national laboratory enables us to see synergies across a broader range of national programmes and government priorities in areas such as clean energy, defence, nuclear forensics and space power.

NuClear Science in depth

The UK’s civil store of plutonium comes from different types of reactors and two reprocessing plants, so there are different mixes of plutonium isotopes, powder morphologies, can atmospheres and temperatures.

Plutonium is arguably the most bespoke and complex element in the periodic table. This, together with the unique storage environment and long timescales, means there are a lot of factors to consider. This is a challenging multi-dimensional scientific problem even before you consider the hazards of handling and studying plutonium materials.

As plutonium undergoes natural radioactive decay, it emits primarily alpha radiation while changing into other elements and isotopes. During storage, plutonium materials are subject to intense alpha radioactivity emissions and, in some cases, high temperatures from self-heating resulting from radioactive decay. This leads to physical and chemical changes, both in the plutonium powders and in the atmosphere above the plutonium. We must understand these changes to ensure the safe long-term storage of plutonium and to efficiently design new processes that will treat it in the future.

Separated plutonium is stored in packages as plutonium dioxide (PuO2). Due to the original production and packaging processes, the powders have adsorbed trace amounts of moisture (water vapour) and other gases. These chemical species are affected by the radiation and temperatures they are exposed to during storage, undergoing myriad chemical reactions.

As well as helium gas generated naturally by the radioactive decay of plutonium, the risk of hydrogen gas generated from radiolysis of the moisture, potentially leading to a build-up of pressure inside the package, must be assessed. Research carried out at UKNNL has helped understand the mechanisms that affect helium and hydrogen production, explaining why packages are not pressurising from hydrogen and safe conditions are maintained.

At the microscopic level, the powder is porous. The pores can have a diversity of sizes and connectivity which affect how gas and moisture interact with the surface of the powder. The effect of radioactive decay (which causes the plutonium powder to heat up) means that the plutonium, and the surrounding atmosphere in the package, is changing even as you measure it. Even the small variations in composition of the atmosphere or the powder can make a remarkable difference to what is produced by the chemical reactions that the radiation initiates. The interplay of all these factors must be understood.

Heat treatment process for legacy chloride-contaminated PuO2

Sellafield Ltd is currently building a £1bn plant to repackage plutonium. The Package Surveillance programme is providing data on standard Thorp and Magnox derived PuO2 powders and their packages that will help underpin the design of the plant. However, there is a small quantity of old PuO2 contaminated with chlorine from degradation of the PVC bags that were used in the 1970s. This material also contains high levels of moisture and so must be stabilised before repacking into modern packages in Sellafield Product and Residue Store Retreatment Plant. Between 2012 and 2019, UKNNL worked with Sellafield Ltd to characterise samples of these materials, understand the chemistry that was occurring at the PuO2 surface and develop a heat treatment process that could stabilise the powders. This work provided unique data on a very complex system, as well as a practical process for retreatment. It led to a series of publications in peer-reviewed journals, including ref. [1] below which described the heat treatment of samples and characterisation of the materials by scanning electron microscopy.

1.Kevin Webb, Robin Taylor*, Catherine Campbell, Michael Carrott, Colin Gregson, Jeff Hobbs, Francis Livens, Chris Maher, Robin Orr, Howard Sims, Helen Steele, Sophie Sutherland-Harper, Thermal processing of chloride contaminated plutonium dioxide, ACS Omega 4(7), 12524-12536 (2019)

Using UKNNL’s plutonium science base to support national programmes and find new uses for materials

A decade of research has led to a breakthrough and a new use for a by-product of plutonium’s radioactive decay. UKNNL has developed a new separation process which can now recover americium-241 from plutonium oxide. The recovered americium can be used in spacecraft power and heating units, leaving the plutonium oxide cleaner than before.

The process has been proven at lab scale in UKNNL’s PuMA Lab, and the UK Space Agency (which will become part of the Department for Science, Innovation and Technology in 2026) is now funding the commissioning of a new bespoke laboratory, PuMA2, to produce enough americium for use in the European Space Agency’s missions in the 2030s.

“With its unique scientific and technical capabilities, UKNNL has a key role to play in supporting the Nuclear Decommissioning Authority, Sellafield Ltd and Nuclear Waste Services in delivering the government policy to immobilise plutonium and put it beyond reach.”

Danny Fox

Chief Strategist: Nuclear Fuel Cycle Nuclear Decommissioning Authority

“The excellent work UKNNL does supporting the Sellafield Ltd Pu Science and Package Surveillance programmes is vital to the Special Nuclear Material (SNM) value stream delivering our mission.”

Dr Jeff W Hobbs

Head of Technical, Special Nuclear Materials Sellafield Ltd

The flagship package surveillance programme at UKNNL

At UKNNL, experimental studies underpinning plutonium storage comprise two basic approaches: small-scale laboratory science-driven experiments, and destructive analysis of plutonium packages from storage. This is part of the Sellafield Package Surveillance Programme, where packages are sent to UKNNL’s Central Laboratory.

Commissioned in 2016, the High Alpha Facility in UKNNL’s Central Laboratory is a world-leading resource for analysing the state of packages and plutonium materials they contain.

Through its work on plutonium, the facility is producing first-of-a-kind data, including on gas compositions, helium release rates, powder morphologies and package condition monitoring. These are transforming the knowledge base underpinning safe, long-term storage of plutonium oxide at Sellafield.

A unique aspect of this programme is the plutonium Can Processing (PCP) glove box line in which plutonium cans are punctured to sample the gases contained within. The gases are extracted and then sent for analysis by gas chromatography.

“As deputy technical lead for the Sellafield Package Surveillance Programme, I have had the opportunity to develop and run a major project which has been a hugely valuable experience both in terms of new techniques developed in the laboratory and skills gained across the whole team. For example, training early careers researchers in plutonium active operations which are vital for maintaining alpha skills in this area of work, ensuring we are continually building expertise and capacity for the future.

“Additionally, in collaboration with the NDA I have had the opportunity to set up a Community of Practice on MOX enabling experts from across the industry (including academia) to meet and discuss topics surrounding MOX, sharing knowledge and expertise in an environment that is not necessarily possible in our everyday jobs. Recent meetings have involved Orano sharing their experience on mixed oxide (MOX) fuels for the MELOX plant in France.”

Hannah May Colledge

Technology Manager (Pu Science) Pu & Radioisotopes Team, UKNNL

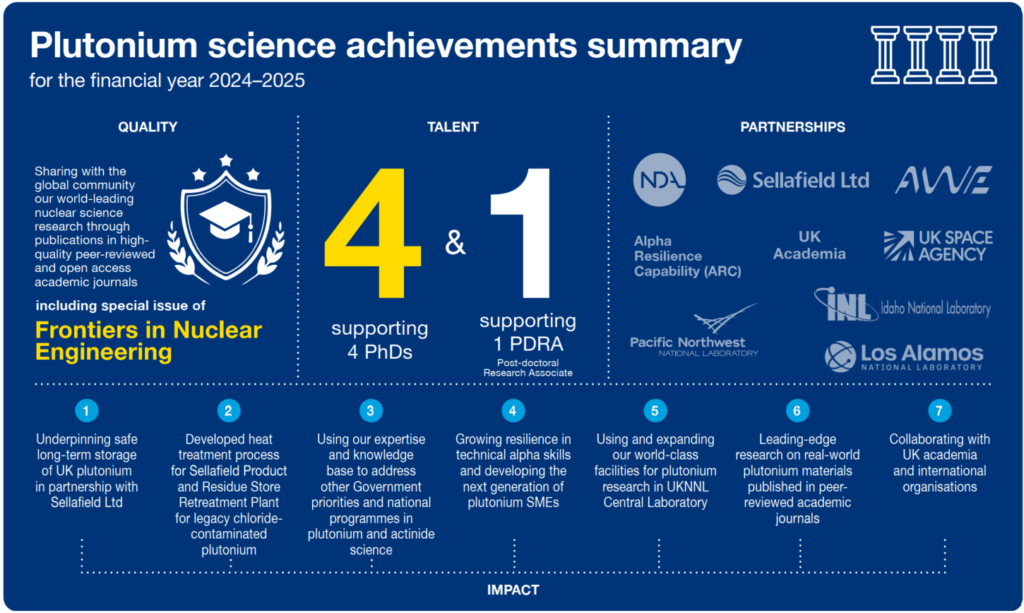

Publication, collaboration and skills

As well as UKNNL’s wide range of plutonium programmes for customers, its skills base is enhanced by participation in the Alpha Resilience Capability project(ARC) which is a major investment in plutonium skills made by the UK Government.

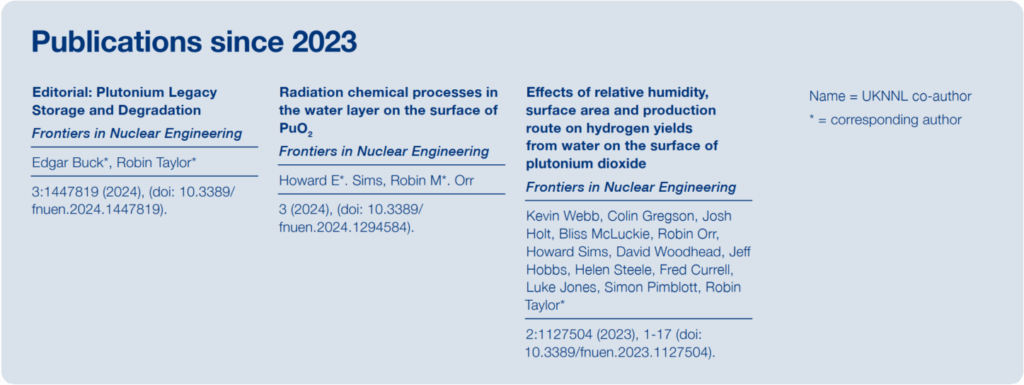

UKNNL regularly shares its findings with the scientific community, with scientists at all levels of their career presenting at international conferences and publishing their results in peer-reviewed academic journals. Doing so ensures the UK remains at the forefront of research and actively demonstrates progress while gaining valuable insight from other research carried out in other nations.

One example is UKNNL’s collaboration with Pacific Northwest National Laboratory in the US in 2024. Together the organisations co-edited a special issue of the Frontiers in Nuclear Engineering journal focused on “Plutonium Legacy Storage and Degradation”.

As well as work for customers, UKNNL itself invests in plutonium science. Through this self-funded work, it aims to provide a steppingstone to boost new ideas and innovations for the industry while offering excellent development opportunities for earlier career researchers and technical leadership opportunities for the next generation of subject matter experts.

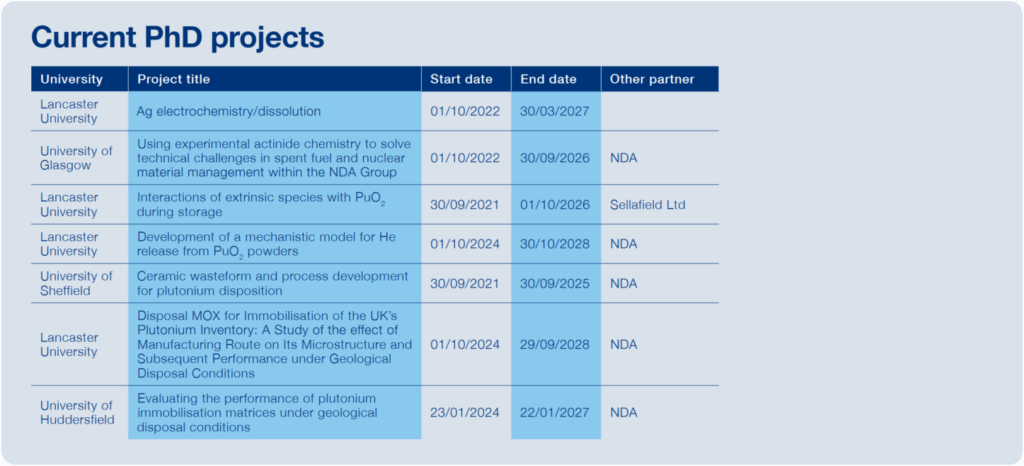

UKNNL’s Science and Technology investment also supports collaborations with UK universities (PhD training and post-doctoral research in plutonium science) and internationally.

The Alpha Resilience Capability (ARC) project

The UK ARC Programme is a proactive collaboration, bringing together experts from the ARC partner organisations to identify synergies and opportunities to address challenges in our alpha areas. At UKNNL, we manage the ARC Technical workstream through six cross-industry

Communities of Practice in:

- Plutonium Properties

- Decommissioning & Decontamination

- Hydrogen & Radiolysis

- Polymers

- Analytical

- MOX

Projects supported by ARC include:

- Radiolytic hydrogen generation in heterogenous systems

- Guidance on safe and secure handling of actinides in academia

- Development of a method to examine plutonium powder samples by transmission electron microscopy (TEM)

Frontiers in Nuclear Engineering

Between 2022 and 2024, six open access articles on the theme of “Plutonium Legacy Storage and Degradation” were published in a Research Topic (special issue) of the journal.

The topic was edited by Dr Edgar Buck of Pacific Northwest National Laboratory (PNNL) (USA) and Dr Robin Taylor (UKNNL) and UKNNL published two articles.

These summarised our theoretical knowledge of radiation chemical reactions on the PuO2 surface and the results of a decade-long experimental programme measuring hydrogen generation from water radiolysis on PuO2.

Additionally, Drs Buck and Taylor published an editorial to frame the key issues in plutonium storage covered by the topic.

See https://www.frontiersin.org/research-topics/41491/plutonium-legacy-storageand-degradation for further information.