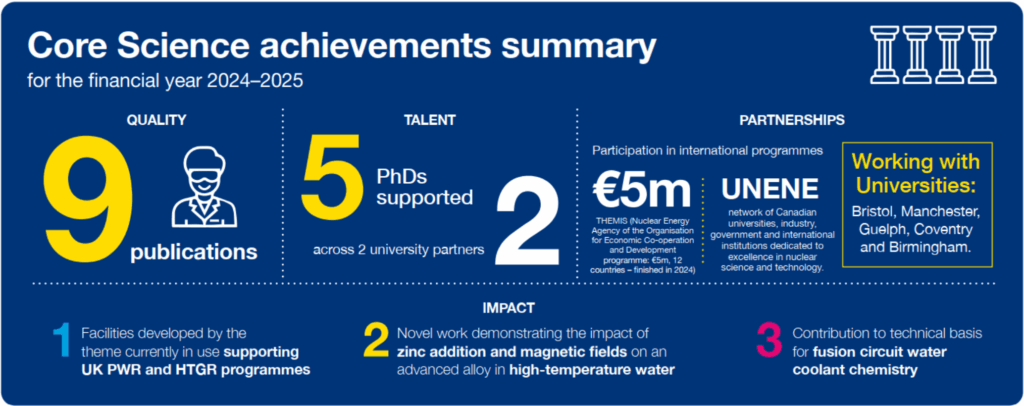

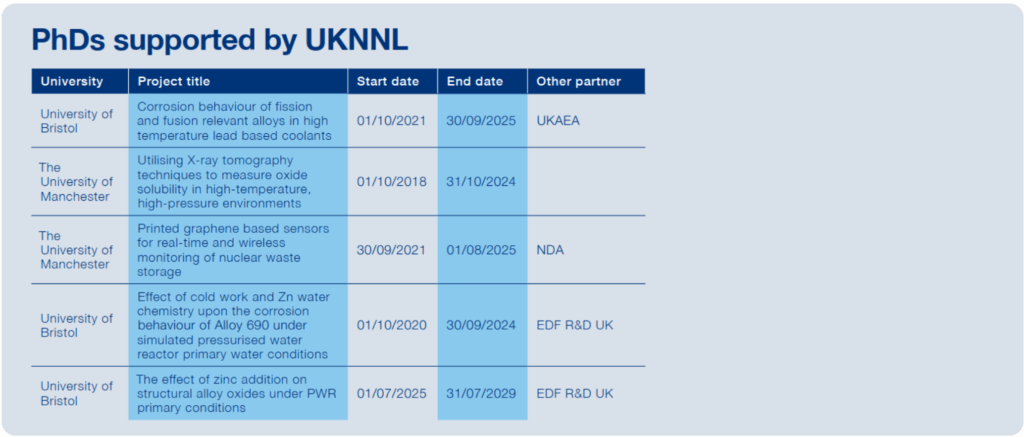

Through a partnership with the University of Bristol, UKNNL is working to test and develop materials and chemistry improvements for both the current and next generation of nuclear reactors. This innovative work means that as new reactor technologies move into detailed design phases, the conditions experienced by materials used in coolant circuits can be optimised, maximising the lifespan of each plant.

The research also has implications internationally as nuclear power continues to be a cornerstone of the global response to the push for net zero.

As the nation embarks on a mission to develop clean, reliable sources of domestic energy, reactor technology will continue to evolve to meet the expected increased demand for both power and heat.

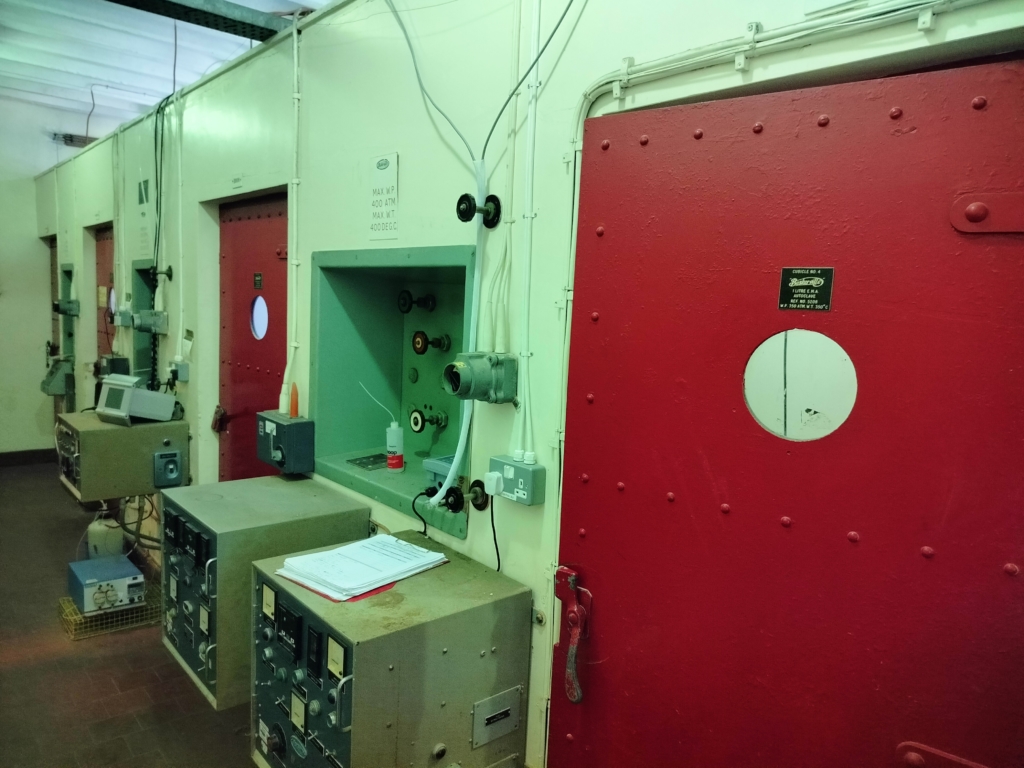

These emerging technologies require extensive research and development. In response, UKNNL has created an advanced testing facility for reactor coolant systems, repurposing existing infrastructure through a partnership with the University of Bristol.

The importance of understanding coolant circuits

Coolant circuits remove heat from the reactor core, where nuclear fission occurs, and transfer the heat as steam to generators to create electricity. Typically, two circuits are used in series to ensure radioactive materials are safely contained.

There is a profusion of different technologies, including many primary coolant types. In some cases, operating experience is limited, often requiring material performance to be inferred from historical test reactor programmes which operated under different conditions or shorter timeframes than required for a nuclear power plant. Designing a modern plant often requires additional data and simulation to predict and validate performance under actual plant conditions.

Additionally, the nuclear sector has a mission to learn from other high integrity and highly regulated industries to adopt innovative technologies to reduce costs and timescales. This is notoriously difficult in such an environment where nuclear safety is an overriding priority. The ability to carry out initial testing of unproven technologies in a lower risk environment which replicates important reactor parameters is a key enabler for successful technology transfer.

By building a testing facility now, UKNNL is supporting future reactor deployment. It also enables its scientists to research technology that will appeal to an international community, while developing necessary skills here in the UK.

NuClear Science in depth: Advanced coolant chemistries for today and tomorrow

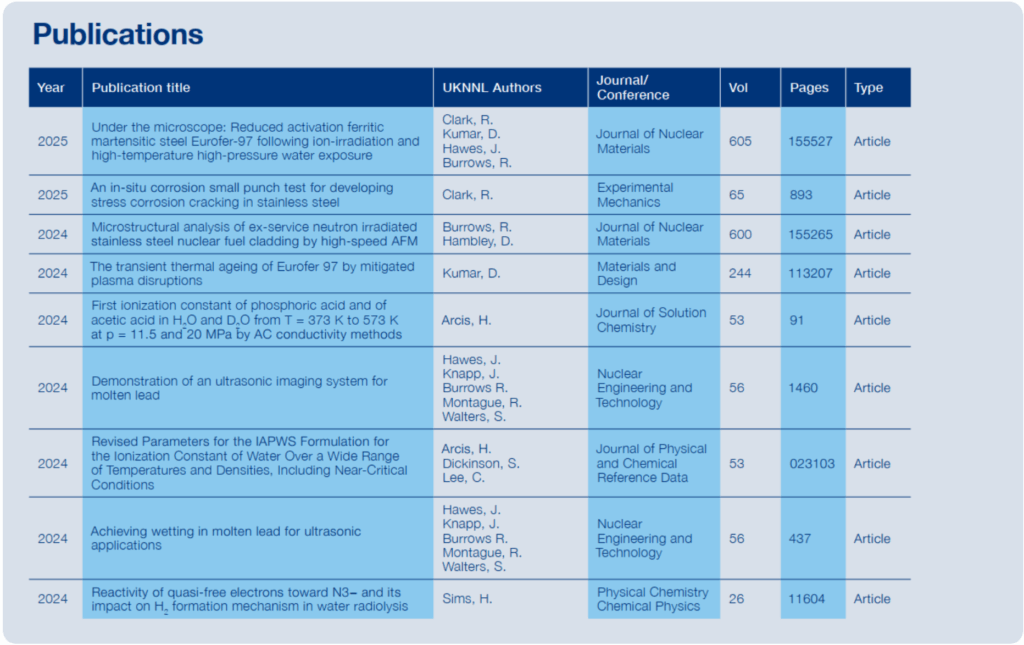

The effect of dissolved zinc in primary coolant water on circuit surfaces has been recognised and exploited for several decades, although the mechanisms are not fully understood.

Steels and nickel-based structural alloys, which – aside from the fuel clad – constitute most of the coolant-facing surface area of a pressurised water reactor (PWR) or boiling water reactor (BWR), tend to oxidise very slowly in high-temperature water. However, even at very low rates, corrosion products released at part-per-billion (ppb) levels can interact with the reactor core and lead to increased production of radioactivity which increases waste and dose to the workforce.

In extreme cases, this interaction can lead to build up of thick crud which can affect fuel integrity and core neutronics, causing nuclear safety issues which would result in reactor output being reduced. Where zinc is present in the coolant (also at very low levels), this is taken up into the alloy oxides and modifies their structure to become denser, more adherent and more protective. In turn, this reduces the corrosion product release rate, effectively ‘turning off’ the main reaction driving this source term.

This effect was originally identified unexpectedly, owing to inadvertent presence of zinc in the primary circuit, and was developed as a mitigation for both corrosion product release and stress corrosion cracking, which can initiate in some alloys in areas of high stress.

To realise the full benefits of zinc chemistry, research work undertaken with the UKNNL’s Bristol facility has examined the interactions of zinc at tens of ppb concentrations on very specific materials.

Samples of steam generator tubes specific to power stations, sampled from the fabrication process prior to installation, were exposed to quantify the differences in uptake and oxide characteristics arising from subtle differences in the fabrication route, but which could prove important in long-term operational performance.

The effect of zinc on advanced materials has also been studied by the Reactor Chemistry and Corrosion team as part of the first zinc exposures of a reduced activation ferritic martensitic steel developed for fusion applications, with similar testing underway of refractory high-entropy alloys.

The work showed that this advanced steel alloy interacted with zinc in a similar way to more conventional materials, paving the way for this chemistry to be applied in PWR-like fusion water coolant circuits of the future.

Securing the effective operation of the UK’s gigawatt nuclear plants

Globally, water is the most widely used nuclear reactor coolant, including the gigawatt-scale PWR in operation at the Sizewell B power plant, and the UK’s most progressed new build project, Hinkley Point C. Water cooling will also be the basis for near-term small modular reactors in the UK.

Teams from the University of Bristol are using UKNNL’s facilities to research the implications of water-cooled nuclear reactors. Hinkley Point C is expected to operate for the next 60-years, so researchers from the University of Bristol are using the UKNNL testing facility to understand the fundamental aspects of very slow corrosion processes. They are using samples from the components that comprise plant in new power stations. These are exposed to high-temperature, high-pressure water in test loops formed of thickwall pressure vessels integrated with temperature, chemistry and pressure control and measurement devices, to allow a range of conditions to be applied and maintained over weeks and months while coolant is recirculated. Although extensive development has been undertaken internationally to understand the performance of structural materials, the new designs will operate for longer and are expected to perform to a range of new regulatory standards.

“ Our partnership with UKNNL on reactor chemistry and corrosion has been a great multiplier of research success. The University of Bristol and UKNNL (as well as EDF) have together developed a capability in chemistry testing for water-cooled reactors (PWR and SMR) and advanced reactors using novel coolants.

“ Through small pilot research programmes, we have built the testing and characterisation capability into a nationally important capability, with a number of PhD students and postdoctoral researchers funded on this topic, publications in respected materials and corrosion journals and presentations at international conferences.

“ Our work together has enabled collaborations with international partners, and the outputs of our research work have direct impact into EDF’s research and development programme for current and future reactors, informing their safety cases for lifetime extension and new reactor construction, as well as supporting the development of coolant circuits for fusion reactors.

“ Our close collaboration with the UKNNL Reactor Chemistry and Corrosion team allows us to be agile to developments in the field, and develop new capability quickly to establish our track record to meet the challenges of future nuclear energy.”

Professor Tomas Martin

University of Bristol

The interactions with the reactor core with part-per-billion (ppb) levels of corrosion products that are gradually released from circuit pipes is at first glance a subtle phenomenon. However, due to the extremely high mass transport in a PWR, this effect can dominate production of operational radiological wastes and worker doses for commercial power plants. Mitigations are being developed by industry to optimise their effectiveness and to support application to new classes of material.

As well as experimental investigations, another key area is the numerical modelling of fuel deposit chemistry of this effect at microscopic scales. Enabling a link between experimental studies and simulation is a priority of the programme.

Coolant testing facilities enable the next generation of reactor technology

UKNNL is working in partnership with the Japan Atomic Energy Agency on the design of a HTGR, which uses helium gas as a coolant. Commissioning a HTGR demonstrator will require underpinning research to understand how high-temperature helium will interact with reactor components.

UKNNL has commissioned a helium loop testing facility at full commercial HTGR temperatures and pressures to support the research needed to understand the processes involved. The facility was built by reusing components from the former Berkeley Technology Centre, close to Bristol, UK. Equipment was originally used in rigs which underpinned lifetime extension of the Magnox nuclear power station at Wylfa, on Anglesey, UK. Wylfa is widely considered the forerunner of a generation of advanced gascooled reactors which have formed the backbone of the UK’s nuclear generation for decades.

In collaboration with the University of Bristol and EDF Energy, the UKNNL team have completed technology neutral tests with reference materials representing different reactor components. The results enable understanding of how impurities in the coolant could interact at the microscopic scale and change material properties over many years or decades.

Other organisations are accelerating advanced reactor designs based on a variety of coolants – including lead and salt. It is necessary to evaluate how the differences between coolant options translate into corrosion and coolant chemistry when circulated at high temperatures and pressures around and through the fuel assemblies.

Molten salt reactors are also in development around the world and require coolant testing facilities to increase their readiness to market. Each technology has different requirements but can benefit from expertise in high-temperature testing and characterisation. As the UK’s national laboratory, UKNNL is developing a range of facilities to test the chemistry and corrosion of these mixtures, using highly specialised apparatus. This ensures the UK has fully up-to-date knowledge and capabilities for the range of technologies that could contribute to a clean energy future.

NuClear Science in depth: Enabling innovation in component development

A major barrier to the deployment of innovative technologies in the nuclear sector is the difficulty in testing early-stage components in the highly unusual and sometimes adverse conditions of a reactor core and primary circuit. This is particularly true for fluids which have very specialised handling considerations such as helium, molten lead and molten salts.

By providing apparatus where early-stage components can be tested before they are ready for on-plant deployment, we can significantly reduce development time and lower technical risks. Examples of this have included the demonstration of high-temperature ultrasound transducers in molten lead, which allowed the first three dimensional imaging in this coolant.

Seal material testing is another significant consideration for high-temperature systems and has been addressed through developing assemblies where material performance can be established under a high differential pressure, as well as representative temperature conditions. A wireless digital implementation is currently underway with the aim to underpin eventual use of resilient communication protocols for plant sensing and control.

Impact – learning from the past to underpin the future

Work at the testing facility builds on decades of experience gained by operators across the nuclear industry. It will provide the information to predict plant operational lifetimes or support plant life extension.

Our partnership with the University of Bristol not only supports world-class science but also provides a valuable skills pipeline. This leverages other tasks within the Reactor Chemistry and Corrosion theme, including an “excellence in reactor chemistry” initiative which has included compilation of multimedia training resources from lifetime experts particularly in light water reactor primary chemistry and steam/water secondary circuits. This complements the experience available from running exposure tests at the coolant facility.

The University of Bristol offers one of the UK’s few postgraduate master’s courses on nuclear science and engineering. It has an enviable record of student entry into the nuclear industry, including PhDs. In fact, UKNNL has recruited some of the students who used the testing facility in their studies.

The testing facility is a valuable resource for both UKNNL and researchers from universities across the UK. It provides a rapid response to emerging research challenges and facilitates knowledge transfer to a new generation of scientists. UKNNL’s testing facility provides easy access for researchers and has typically hosted the research work of up to four PhD and postdoctoral researchers concurrently. Partnerships both now and in the future will enable innovations that will further strengthen the sector and attract new talent.

Developing advanced testing regimes to support innovation

Coolant systems are also required for fusion reactors, with high temperature water being one of the frontrunner coolants, where the fusion industry will benefit from the decades of operational experience gained from water-cooled fission reactors.

UKNNL is working alongside the UK Atomic Energy Authority (UKAEA), responsible for developing the UK’s fusion technology. Fusion programmes are using a range of complementary water testing loops under national and international programmes (e.g. EUROfusion) to develop a suitable water chemistry to build confidence in the durability and performance of the facing structural alloys.

UKNNL built a bespoke module to enable testing, applying very high magnetic fields to simulate the plasma confinement systems in a tokamak. It has provided the first data on high magnetic field influence on advanced reduced activation steel in a representative cooling circuit environment.

UKNNL has also worked on various test methodologies for accelerating material development, such as the use of in situ miniaturised stress/strain rigs and surrogate ion irradiated materials in high temperatures.

The team is also working with another University of Bristol-led international partnership to develop a unique high temperature atomic force microscope.

Having these facilities means that UKNNL can engage with a range of research initiatives, including the collaborative European EUROfusion programme and the UK Government’s Advanced Modular Reactor Research and Development programme, supporting the deployment of these reactors to contribute to net zero goals.